Jig nthawi zambiri imakhala ndi chinthu choyikirapo (kuti mudziwe malo olondola a chogwiriracho), chipangizo chowongolera, chowongolera chodulira (kuti mudziwe malo omwe ali ndi chodula ndi chogwirira ntchito kapena chodulira chowongolera), kugawa chipangizo (kuti chogwiritsira ntchito chitha kumaliza kukonza masiteshoni angapo pamakhazikitsidwe awiriwa, kuphatikiza chipangizo cholumikizira chozungulira komanso chozungulira), cholumikizira ndi thupi lokonzekera (chikhazikitso), etc. ndi zina zotero, zomwe makina a jig ndi ofala, omwe nthawi zambiri amafupikitsidwa ngati jig.Pamene pokonza zida zogwirira ntchito pa chida cha makina.Kuti apange pamwamba pa workpiece kukumana ndi luso luso miyeso, akalumikidzidwa geometric ndi mwatsatanetsatane malo malo ena otchulidwa mu zojambula, workpiece ayenera atakhazikika, pabwino ndi clamped pamaso processing.

Mitundu ya Jig ikhoza kugawidwa mu: ① jig yapadziko lonse.Monga makina vise, chuck, sucker, mutu wogawanitsa ndi tebulo lozungulira, ndi zina zotero, zimakhala ndi universality. Zingathe kusintha bwino ndi kusintha kwa ndondomeko ndi kukonza zinthu.Mapangidwe ake adapangidwa, miyeso yake ndi mafotokozedwe ake adasanjidwa, ambiri mwa iwo asanduka chowonjezera chokhazikika cha zida zamakina.② Jig yapadera. Imapangidwa mwapadera ndikupangidwa kuti ikwaniritse zosowa za gawo lazogulitsa munjira inayake.Chinthu chautumiki ndi chapadera komanso cholunjika kwambiri.Nthawi zambiri, amapangidwa ndi wopanga. Nthawi zambiri, amaphatikiza lathe jig, mphero yamakina, kubowola kufa (makina chida chowongolera chodulira kuti kubowola kapena mabowo opangira pa workpiece), boring kufa (makina chida jig chowongolera chida chotopetsa. dzenje pa workpiece) Ndi kutsagana ndi jig (ya foni yam'manja pa mzere wodziwikiratu wa chida chophatikizika cha makina) ③ Jig yosinthika. Jig yapadera yomwe ingasinthidwe kapena kusinthidwa kuti ikhale zigawo. mafotokozedwe ndi ma USES ndi oyenera kupanga zoyeserera zatsopano ndi zidutswa zamunthu, kupanga magulu ang'onoang'ono ndi ntchito zosakhalitsa zomwe zimasinthidwa pafupipafupi ndi zinthu zatsopano.Kuphatikiza ndi vice, chuck, kugawa mutu ndi tebulo lozungulira, palinso chodula chophatikizira wamba.Nthawi zambiri, pamene mawu odula ndi jig akuwonekera nthawi imodzi, ambiri a jigs amatanthauza chodula chogwirira.

lati jig

Chipangizo cha jib chomwe chimagwiritsidwa ntchito pokonza zamkati, zakunja ndi zamtundu wa zogwirira ntchito pa lathe zimatchedwa jig device ya lathe.Zambiri za lathe jig zimayikidwa pa spindle, zochepa zimayikidwa pa bedi kapena thupi la bedi.

Makina oyezera atatu-coordinates

Amagwiritsidwa ntchito mu makina oyezera ndi chithandizo chodziwikiratu , chipangizo chofotokozera kuti chikwaniritse kusintha kosinthika kwa workpiece pansi pa test.The Chipangizo chikhoza kukhazikitsidwa chokha kuti chithandizire workpiece ndikukhazikitsa mfundo zopanda malire zowonetsera workpiece.Mapulogalamu apadera apadera, akhoza mwachindunji. kudzera mu data ya geometric ya workpiece, mumasekondi pang'ono kuti mupange njira yolumikizira workpiece.

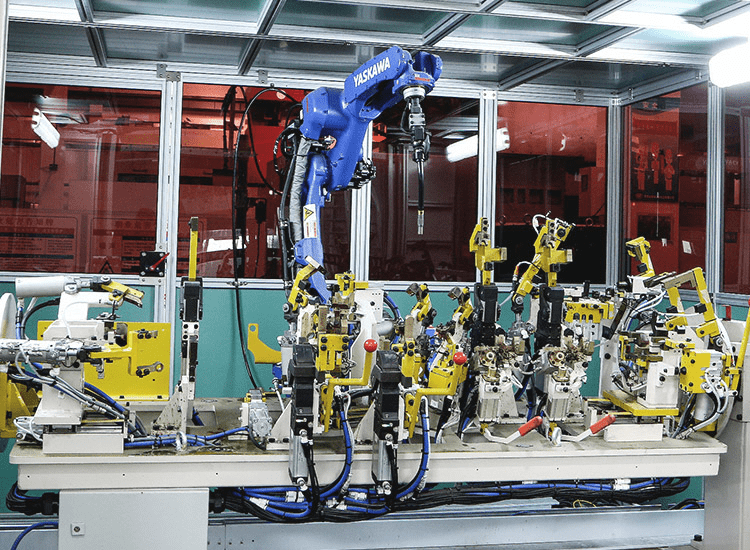

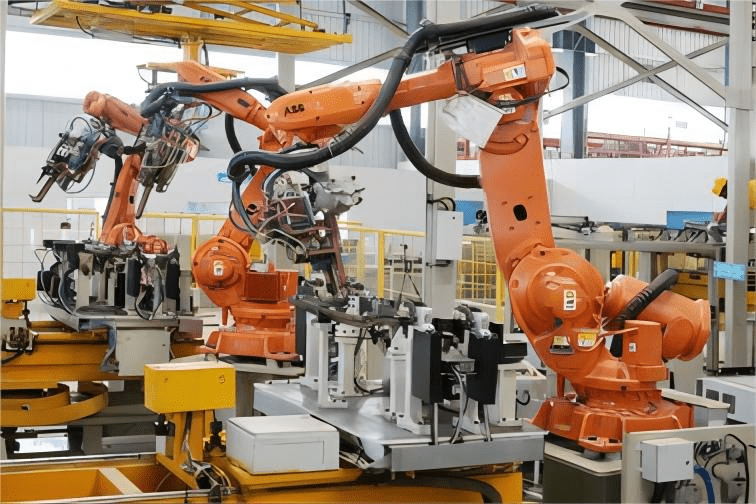

Kukonzekera kwa robot ya mafakitale

Zonsezi zimayikidwa mu maloboti a mafakitale ndipo zimagwiritsidwa ntchito mu zipangizo zopangira mafakitale, zomwe ndi imodzi mwa matekinoloje atsopano a zipangizo zamakono zopangira mafakitale.Ntchito wamba ndikutsitsa zida zamakina, kuyika zida zogwirira ntchito, kuwotcherera, kugaya ndi mafakitale ena osayendetsedwa ndi anthu.

Milling jig

Zonse zimayikidwa pa tebulo la mphero, ndi kayendedwe ka makina odyetsera makina. Zimapangidwa makamaka ndi chipangizo choyikira, chipangizo chokhomerera, chipangizo cha konkriti, cholumikizira ndi chocheka. ndi yapakatikati ndipo kugwedezeka ndi kwakukulu.Choncho, mphamvu yokhotakhota ya makina a mphero ndi yaikulu, ndipo kulimba ndi mphamvu ya chipangizo cha jig ndipamwamba.

Kukhala ndi pedestal jig

Pofuna kuonetsetsa kuti kupanga zonyamula poyambira ndi kupititsa patsogolo khalidwe la kubala pedestal, kuwonjezera pa kugwiritsa ntchito zida makina ndi zida zina zamakina, chiwerengero chachikulu cha zipangizo zamakono adzagwiritsidwa ntchito. Zothandizira zothandizira.Bearing pedestal jig ndi chida chopangira chomwe chimagwiritsidwa ntchito makamaka kutsimikizira mtundu wa zinthu zonyamula pedestal.Itha kupanga njira yopangira zokhala ndi pedestal yabwino kwambiri.Zosintha zosiyanasiyana za bearing pedestal zimasiyanasiyana malinga ndi kapangidwe kawo ndi mawonekedwe, kugwira ntchito. Choncho pali mitundu yosiyanasiyana ya chogwirizira chitsulo, zonse mu kuchuluka kwake komanso kalembedwe. Itha kugwiritsidwa ntchito kudziwa molondola malo ogwirira ntchito. Mwanjira ina, chogwirira ntchito chomwe chiyenera kukonzedwa chikhoza kuchulukitsidwa, kotero kuti kayendetsedwe kofunikira pakukonza workpiece kukhoza kutsirizidwa.chojambula chonyamula chopondapo chimakhala ndi gawo lofunika kwambiri pakupanga, kotero ndikofunikira kwambiri kujambula zojambula zojambula.

Nthawi yotumiza: Jan-06-2023

.png)

.png)