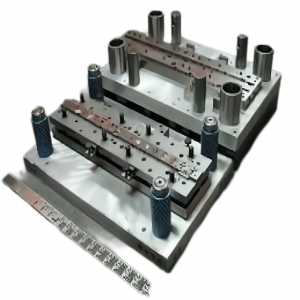

Welding Fixture For Cross Member WS Spring Link

Kanema

Minda Yofunsira

Kuwongolera khalidwe lamakampani agalimoto

Kukhoza kupanga mzere wamagalimoto kumawonjezeka

Kufotokozera

| Mtundu Wokonzekera: | Kuwotcherera kwa Arc |

| Kukula: | 1800x1300x900mm |

| Kulemera kwake: | 125KG |

| Zofunika: | Main Construction: zitsulo Thandizo: zitsulo |

| Chithandizo chapamwamba: | Base Plate: Electroplating Chromium ndi Black Anodized |

Zambiri Zamalonda

Mawu Oyamba Mwatsatanetsatane

Uwu ndi gulu la kuwotcherera kwa WL Cross Member WS Spring Link, kwathunthu mu seti 2, tidapangira makasitomala athu aku Canada. The spring chuck shank ndi cylindrical fixture yomwe imayikidwa mu makina ophera kuti amange chobowola kapena chodula mphero.Lowetsani chuck mu nati wa loko ndipo pang'onopang'ono pindani mtedza wa loko ndi kasupe wa kasupe pa shank, cholumikizira kapena chopotera.Kutengera elasticity wa zitsulo zotanuka kumangitsa, lotayirira achepetsa yabwino, makamaka ntchito clamping kuwala, sing'anga katundu kudula zida.Nthawi zambiri amagwiritsidwa ntchito pokhomerera zida zodulira monga mphero, zobowola, matepi, ma reamers ndi zobowolera pakati.Sinthani ma clamping osiyanasiyana posintha zosonkhanitsa zosiyanasiyana. Mukamangirira, ulusi wa chuck wa kasupe, nati wa loko ndi malo oyika pamwamba ndi chulucho ziyenera kutsukidwa.Pakuyika nati ya chuck ndi loko, mtedza wa chuck ndi loko uyenera kupendekera ku Angle inayake kenako ndikuyika mu loko wa nati wa loko.Osagwiritsa ntchito torque yamphamvu yokulirapo ndiyothina kwambiri, kuti mupewe chida choyipa cha meteorite ndi mawonekedwe ake.

Kuyenda Kwantchito

1. Analandira dongosolo logulira———->2. Kupanga———->3. Kutsimikizira zojambula / zothetsera———->4. Konzani zipangizo———->5. CNC———->6. CMM———->6. Kusonkhanitsa———->7. CMM-> 8. Kuyendera———->9. (gawo lachitatu kuyendera ngati kuli kofunikira)———->10. (wamkati/makasitomala patsamba)———->11. Kulongedza (bokosi lamatabwa)———->12. Kutumiza

Kupirira Kupanga

1. The Flatness of Base Plate 0.05/1000

2. Makulidwe a Base Plate ± 0.05mm

3. The Location Datum ± 0.02mm

4. Pamwamba ± 0.1mm

5. The Kuwunika zikhomo ndi mabowo ± 0.05mm

Njira

CNC Machining(Kugaya/Kutembenuza), Kupera

Electroplating Chromium ndi Chithandizo cha Black Anodized

Maola Opanga (h): 40h

Maola Omanga (h): 150h

Kuwongolera Kwabwino

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Chitsimikizo Chachitatu chochitidwa ndi Shenzhen Silver Basis Testing Technology Co., Ltd, ISO17025 Certified

.png)

.png)