TTM Machinery Precision Die Ndi Stamping Part Zitsanzo

Kanema

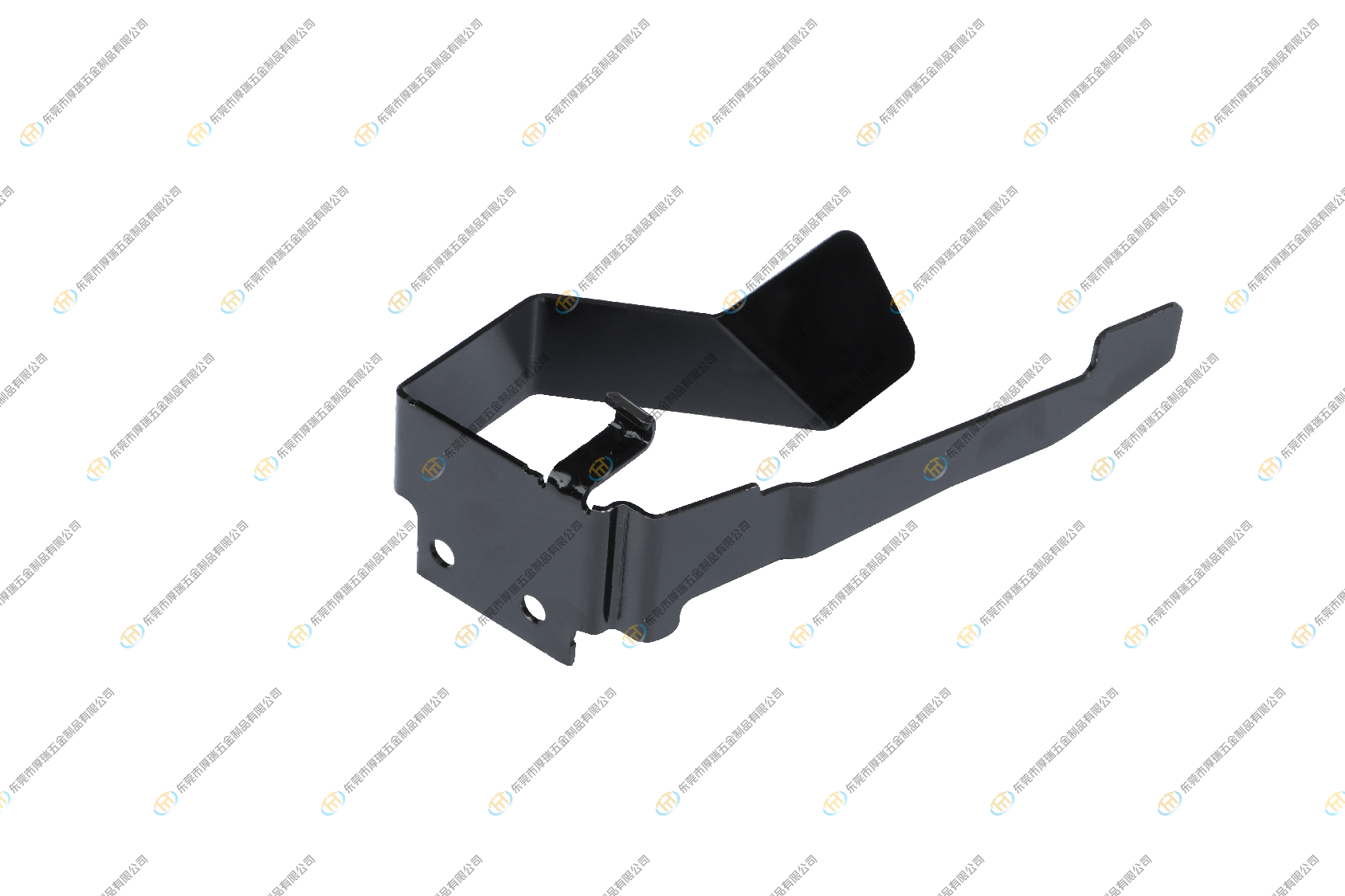

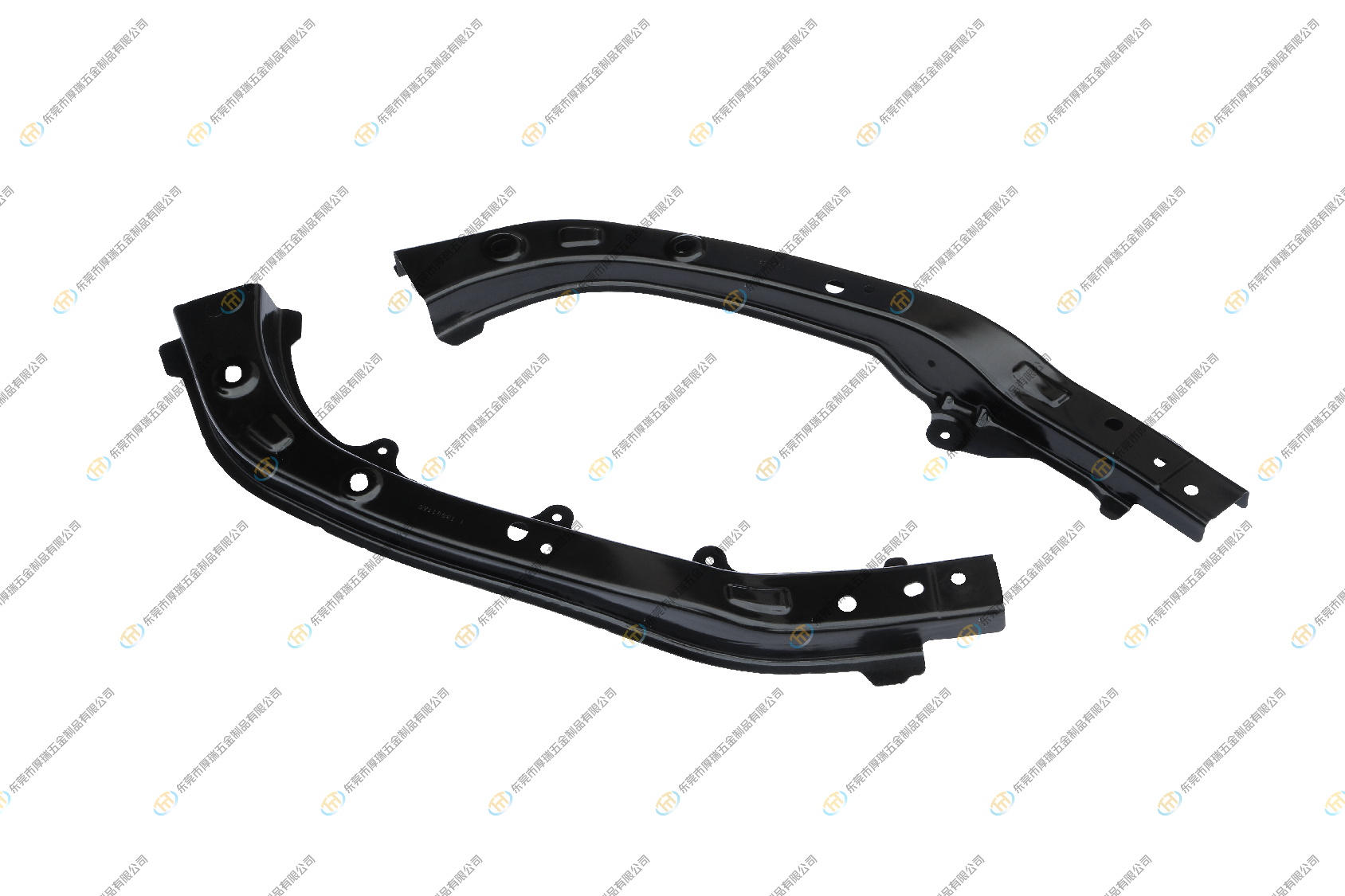

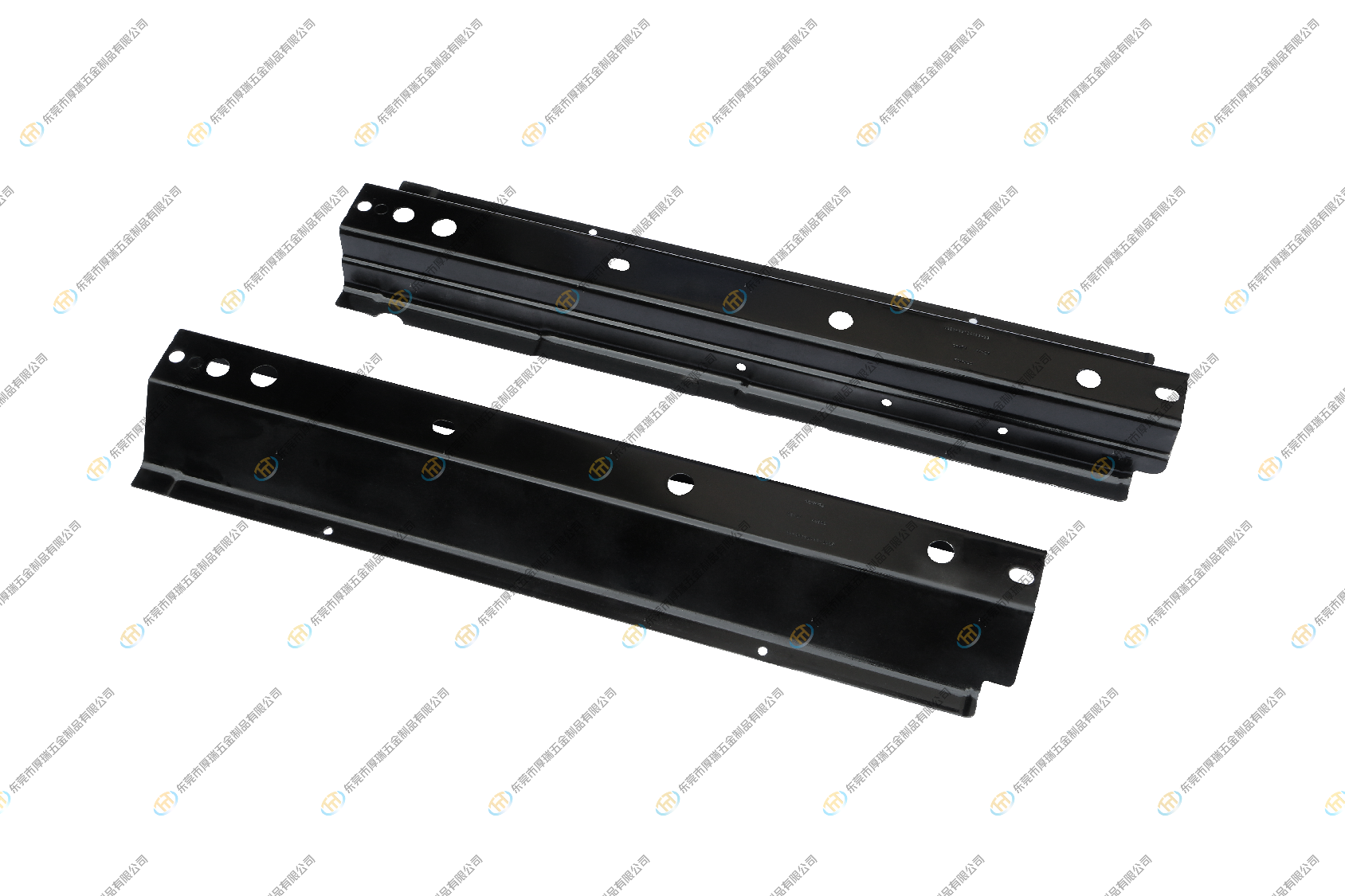

Zigawo

- Mpando kumbuyo

- Battery Cradle

- Cradle

- Main Channel

- ndi zina.

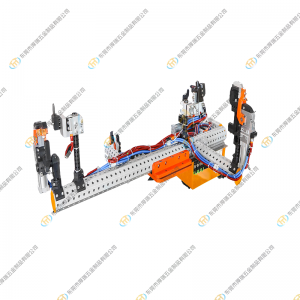

Zithunzi Zopanga

Mawu Oyamba

Zigawo zopondapo zimatanthawuza zigawo zomwe zimapangidwa popondaponda zitsulo kudzera m'mafa.Lili ndi ubwino wolondola kwambiri, kulemera kwake, mphamvu zambiri, ndi zotsika mtengo, ndipo zimagwiritsidwa ntchito kwambiri pamagalimoto, zamagetsi, makina ndi zina.Zitsanzo za gawo losindikizira ndi zitsanzo zina zopangidwa ndi cholinga chotsimikizira ngati mapangidwewo akukwaniritsa zofunikira, kuyang'ana mtundu wake, ndikulimbikitsa msika.Nthawi zambiri, zitsanzo za magawo osindikizira opangidwa ndi TTM amafunikira kuyang'anitsitsa ndikuyesedwa kuti awonetsetse kuti magwiridwe antchito ndi mtundu wawo ukukwaniritsa miyezo ndikukwaniritsa zomwe makasitomala amafuna.

Mayendedwe Athu Ogwira Ntchito

1. Analandira dongosolo logulira———->2. Kupanga———->3. Kutsimikizira zojambula / zothetsera———->4. Konzani zipangizo———->5. CNC———->6. CMM———->6. Kusonkhana———->7. CMM-> 8. Kuyendera———->9. (gawo lachitatu kuyendera ngati kuli kofunikira)———->10. (wamkati/makasitomala patsamba)———->11. Kulongedza (bokosi lamatabwa)———->12. Kutumiza

Kupirira Kupanga

1. The Flatness of Base Plate 0.05/1000

2. Makulidwe a Base Plate ± 0.05mm

3. The Location Datum ± 0.02mm

4. Pamwamba ± 0.1mm

5. The Kuwunika zikhomo ndi mabowo ± 0.05mm

.png)

.png)