Makina Owotcherera a Robot a TTM Arc Welding Automated Welding Fixture

Kanema

Zambiri zofunika

| Chitsimikizo: | 3 zaka |

| Zofunika: | Chitsulo chosapanga dzimbiri |

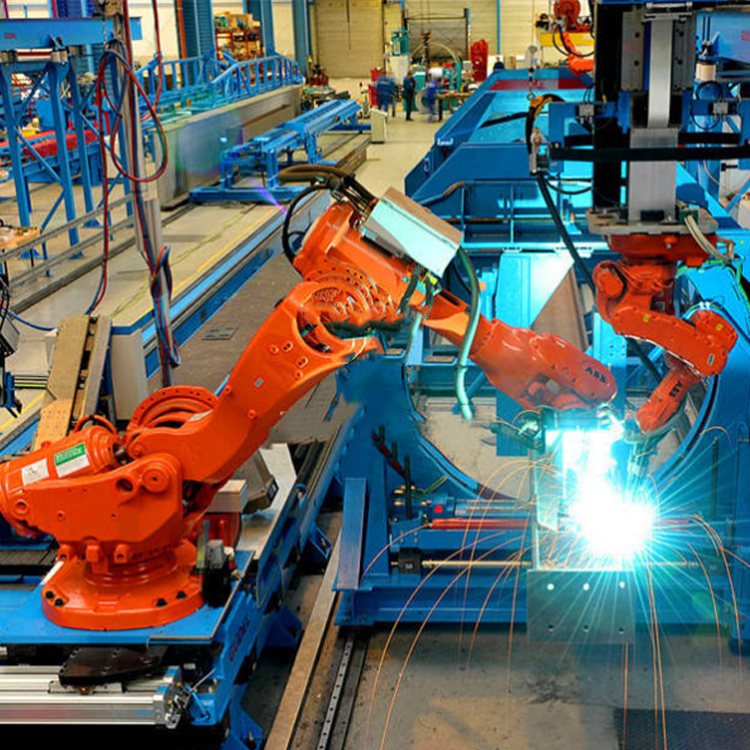

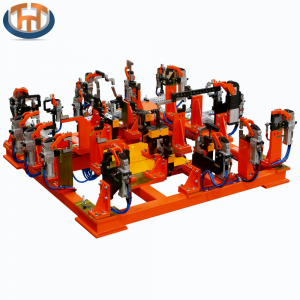

| Kagwiritsidwe: | Kuwotcherera Magalimoto |

| Ntchito: | Magalimoto a Gawo Assembly Line |

| Kulongedza: | bokosi lamatabwa |

Zithunzi Zamalonda

Mawu Oyamba

Ntchito yayikulu yowotcherera ndikuwonetsetsa kukula kwa kuwotcherera, kuwongolera kulondola kwa msonkhano ndikuchita bwino, komanso kupewa kuwotcherera.Pakukonza dongosolo loyenera, njira yopangirayo imatha kukonzedwa bwino kuti ithandizire kukhazikika kwa nthawi yamasiteshoni ndikuchepetsa nthawi yosapanga, potero kumapangitsa kuti ntchitoyo ikhale yabwino komanso yotulutsa.

TTM yadzipereka pa kafukufuku ndi chitukuko cha zida zapamwamba zodziwikiratu

Kuyenda Kwantchito

1. Analandira dongosolo logulira———->2. Kupanga———->3. Kutsimikizira zojambula / zothetsera———->4. Konzani zipangizo———->5. CNC———->6. CMM———->6. Kusonkhana———->7. CMM-> 8. Kuyendera———->9. (gawo lachitatu kuyendera ngati kuli kofunikira)———->10. (wamkati/makasitomala patsamba)———->11. Kulongedza (bokosi lamatabwa)———->12. Kutumiza

Kupirira Kupanga

1. The Flatness of Base Plate 0.05/1000

2. Makulidwe a Base Plate ± 0.05mm

3. The Location Datum ± 0.02mm

4. Pamwamba ± 0.1mm

5. The Kuwunika zikhomo ndi mabowo ± 0.05mm

-300x3001.png)

.png)

.png)